Cold Forging Process

Our Hirohata factory in Hyogo Prefecture is home to one of the largest cold forging facilities in Japan. This factory manufactures cold-forged components such as shafts, shaft gears, cases, and AC poles found in automotive parts including alternators, starters, and electric power steering.

Cold forging is a method that forms metal by applying pressure at room temperature to change its shape, utilizing the plasticity of metal. It is an extremely difficult technique that requires advanced expertise. This method produces significantly fewer metal shavings*1 than cutting methods, so resource conservation is one of its characteristics.

For example, AC poles (key rotor components) used in alternators generally lose approximately 60% of their material when manufactured by conventional cutting methods. However, our cold forging process reduces material waste by approximately 10%, from the metal cutting through to the final forming of the shape.

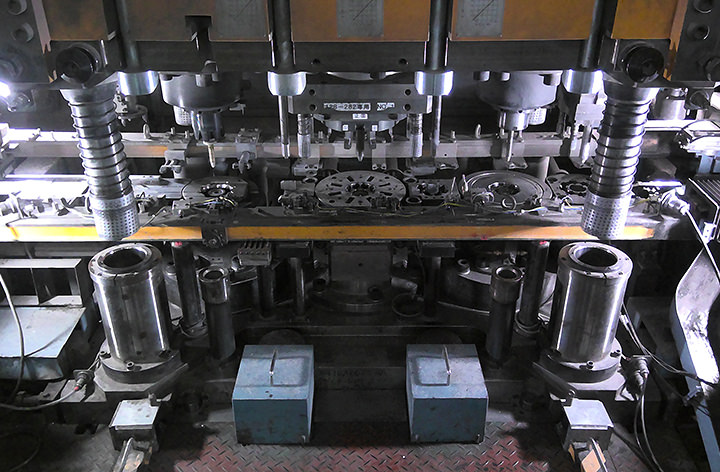

Furthermore, our cold forging uses transfer processing*2 and other proprietary technologies to enable swift mass production that reduces processing time for the same components by about 99% when compared to cutting methods. These technologies enable our factories to conserve steel resources in the manufacturing process and to reduce carbon dioxide emissions, contributing to the realization of a circular economy and a decarbonized society.

- *1)Metal shavings: Scrap or powder produced when metal is cut and processed.

- *2)Transfer processing: A method in which multiple processes are conducted simultaneously in a single press machine. Multiple dies are arranged per process within the equipment and workpieces are moved between processes by a transfer device, enabling continuous press processing and high-speed production.

A view inside our Hirohata factory in Hyogo Prefecture

Transfer processing in cold forging

An AC pole created by the cold forging process