Hot Runner Molding System

We have actively adopted the hot runner molding system for molding plastic materials used in automotive parts, as this method significantly reduces waste. In the conventional cold runner molding system, unnecessary resin inevitably forms in mold runner channels when the molten resin is cooled and solidified in molds. In contrast, excess resin is not generated with the hot runner molding system.

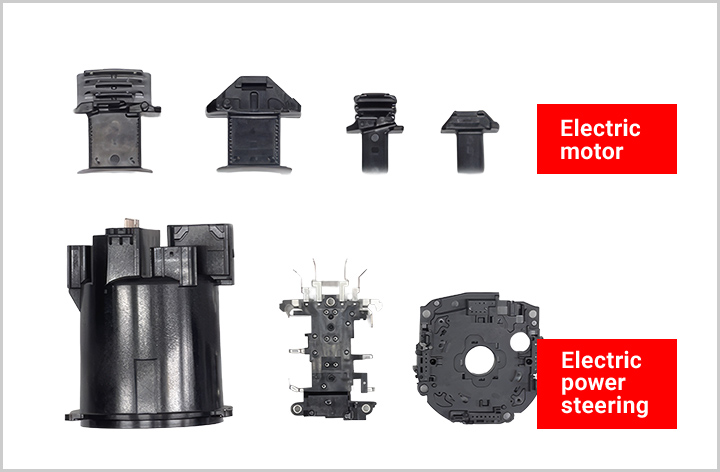

Super engineering plastics that are able to withstand harsh operating conditions, including high temperatures, are being used in automotive plastic components. Although these plastics require more advanced molding technologies than standard resin components, we have fully applied our manufacturing expertise accumulated over the years to utilize the hot runner molding system even for resin components that use super engineering plastics, such as those in automotive electric motors and electric power steering systems. This initiative has resulted in the reduction of approximately 400 tons (calculations based on our 2024 production levels) of excess resins, significantly contributing to resource conservation.

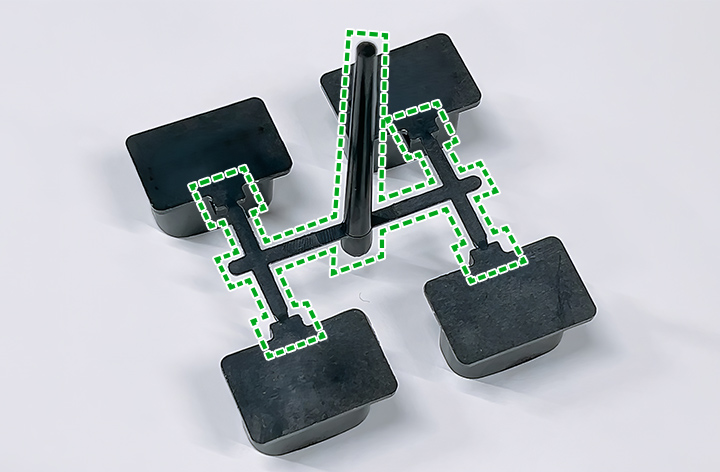

Through our hot runner molding system, we have reduced the unnecessary resin (in the area outlined with a dashed line) that is inevitably formed with the cold runner method.

Examples of products manufactured with the hot runner molding system